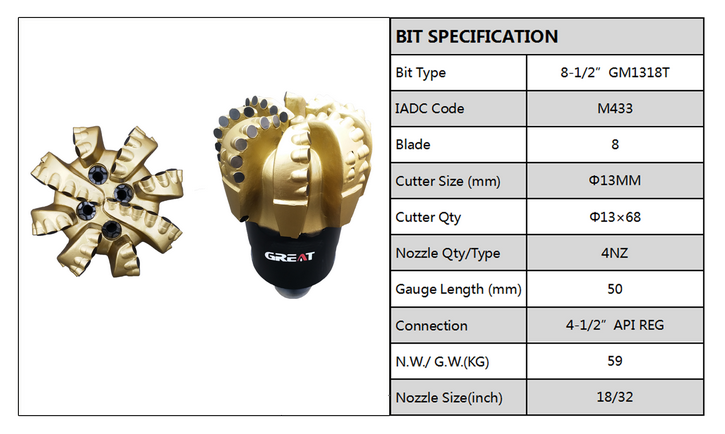

GM1318T

The optimization GM1318 has proven to increase bit performance across a range of medium formations and operating parameters.

The optimization GM1318 has proven to increase bit performance across a range of medium formations and operating parameters.

Advanced tungsten carbide material matrix body 20% improvement in erosion resistant than precious matrix bit Less cutting structure less and bit body damage Provide multiple advantages in interbeded lithology. Enhanced bit stability for BHA shock and vibration mitigation. Increase cleaning and reduce balling. PDC cutter technology made a perfect performance on impact strength resistance and abrasive resistance. Dual row cutter extend the aggressiveness and durability. The FEA software for the cutters distribution and layout made the drilling more efficient and reduce NPT. Optimize the angle of the cutter in both axial and radial by FBS(force balance analyze) software resulting in stronger aggressive and more durability of the bit. DOC(depth of cutters) was calculated and optimized by a series experiences of the bit,made the cutter penetrate the formations more rationally.

Short:Improved bit steerability and tool face control for directional or horizontal drilling, reduce slide section by achieve builds more quickly. Extend:Enhances bit stability and allows more area for gauge protection components, improves bole hole quality.

Short:Improved bit steerability and tool face control for directional or horizontal drilling, reduce slide section by achieve builds more quickly. Extend:Enhances bit stability and allows more area for gauge protection components, improves bole hole quality.

Short:Improved bit steerability and tool face control for directional or horizontal drilling, reduce slide section by achieve builds more quickly. Extend:Enhances bit stability and allows more area for gauge protection components, improves bole hole quality.

表单占位