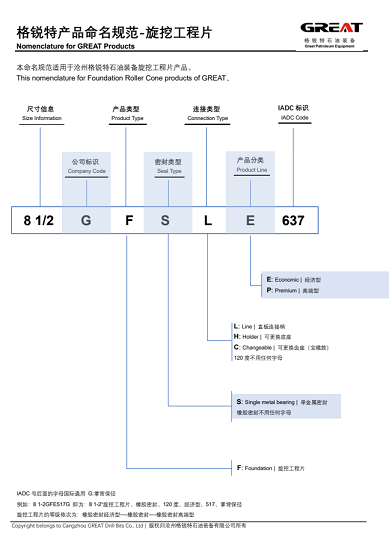

GFH637

High precision rolling bearing, ball lock mechanism, bearing surface inlaid with wear-resistant alloy and silver plated.

It has strong wear resistance and is suitable for high-speed rotation during drilling.

High precision rolling bearing, ball lock mechanism, bearing surface inlaid with wear-resistant alloy and silver plated.

It has strong wear resistance and is suitable for high-speed rotation during drilling.

Design features and structure

1. Mixed tooth arrangement design to improve the wear resistance of the roller cone, specifically designed for rotary excavation engineering;

2. Strengthen the back nail design to protect the cone body and extend its service life;

3.Detachable roller cone bit, only need to weld the base onto the cylinder ring, and the base can be replaced with roller bit 3-4 times after welding. Save welding time, and compared to directly welding the cone bit, avoid damaging the sealing rubber ring of the cone due to high welding temperature, thereby shortening the service life of the cone;

4.The integrated base made by direct forging has high strength and adaptability, and can be reused multiple times. High precision, more perfect fit with the dental palm, improving service life.

Bearing

High precision rolling bearing, ball lock mechanism, bearing surface inlaid with wear-resistant alloy and silver plated. It has strong wear resistance and is suitable for high-speed rotation during drilling.

Sealing and lubrication system

The bearing circular sealing ring is made of HNBR rubber, which has the advantages of wear resistance, oil resistance, high rotational speed, and is suitable for use in various harsh conditions.

表单占位